Implant surgeon Hrisith Choksi explains the benefits to clinicians of working with Atlantis when providing implant prostheses.

From single tooth replacement to full arch implants, implant dentistry has traditionally come with a range of challenges. However, all this is changing fast.

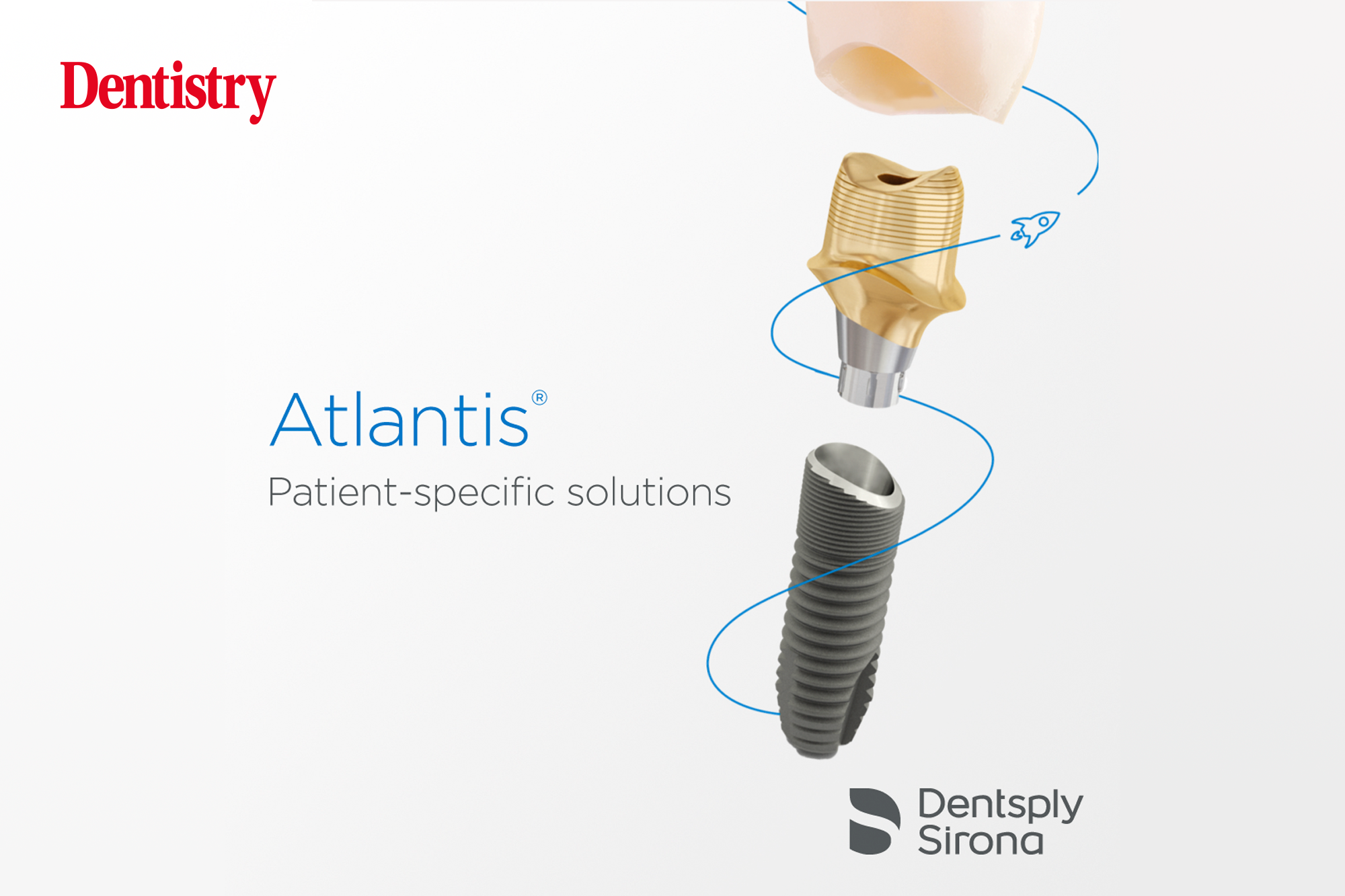

Patient-specific abutments and bars, along with the digitisation of implant prostheses, are simplifying and revolutionising every aspect of implant dentistry. From scanning, treatment planning and placement, through to the final restoration.

I have been working in implant dentistry since 2012. I made my move from an analogue to a digital implant workflow around seven years ago.

We are now a fully digital practice. We have invested in a range of Dentsply Sirona equipment, including a Primescan intraoral scanner and CEREC Primemill milling machine to produce quality chairside restorations and dental implant prostheses. At the same time, we also started to do a lot of work with Atlantis and BridgeBase.

Atlantis abutments

Like so many clinicians nowadays, we no longer take analogue impressions at my practice. All impressions are taken digitally using Primescan.

Once the scans are completed they are sent directly to Atlantis, with case material and prescription for patient-specific abutments. It is a simple ordering process that is completed in minutes. We receive the design back within a couple of hours.

We check the design, sometimes we make a few tweaks, and then we authorise it for production. The finished abutment is then received within three to five days.

Bespoke and flexible implant dentistry

As soon as you authorise the abutment, you can also download the core file from Atlantis to make the crown.

With Atlantis abutments, you can have the Atlantis technicians design and manufacture the crown for you. However, if you prefer, you can design and make the crown yourself using CEREC. Or you can send the core file to your chosen lab or milling partner, or even to your own design team. It’s very flexible.

Personally, I use my own design team at ToothSketch Dental Design. They send back the digital design files for the crown, or whatever implant prosthesis we have prescribed, and we mill it in the practice using CEREC. As soon as the final abutment arrives from Atlantis, the implant prosthesis is ready to fit straightaway. It’s a very sleek workflow.

Atlantis BridgeBase

I also use Atlantis BridgeBase, which provides a metal framework for digital restorations and implant prostheses. It is a bar that can sit exactly in the prosthesis or in the prosthetic envelope.

Once Atlantis has designed the bar we download the files and review them. The files come in different layers so you can examine the seating of the bar, with or without the prosthesis, and with or without the soft tissue.

Once the design is approved, Atlantis fabricates the BridgeBase bar while we download the core file to design our own implant prosthesis. I review the design to see how the prosthesis is seating on the BridgeBase and check the occlusion and appearance. The prosthesis is milled separately at my milling centre in Harrogate and once we receive the BridgeBase bar it is ready for placement straight away.

The benefits of a digital workflow for implant prostheses

Atlantis is a flexible and adaptable system to suit the way you prefer to work. The patient-specific abutments are suitable for all types of cases, particularly for anterior cases where it is often necessary to carry out soft tissue contouring. By using abutments with a gold hue, aesthetics are greatly improved.

Being an open system, Atlantis abutments and implant prostheses are compatible with all major implant systems.

Another benefit of a digital workflow is that it makes no difference where your practice is based, where your design and milling team are based, or even where Atlantis is based. Everyone works seamlessly together to deliver the ideal prosthetic solutions – and faster than ever before.

In my practice, working with Atlantis has reduced the amount of patient visits and chair time significantly. This allows us to see more patients, increase our treatment options and ultimately become a more efficient and profitable practice.

Adopting a digital workflow for implant work makes perfect sense for any practice and the customer support you receive from Atlantis and Dentsply Sirona is second to none. Patient-specific implant prostheses combined with digital technology is the only way to produce what today’s patients need and expect – and there’s definitely no going back for me.

Find out more about Atlantis patient-specific prosthetic solutions, or book a 1:1 consultation with a Dentsply Sirona specialist now.

Adblock test (Why?)